Akụkụ mepere emepe ahaziri maka Bit

uru oghe bit ahaziri ahazi

• Ịmepụta usoro mmepụta ihe ndị ọzọ na-agụnye ike dị ukwuu, ntụkwasị obi na ịdịte aka, yana ike ịmepụta ọdịdị dị mgbagwoju anya na njide siri ike.

• Ma nke forging size na udi na-ahaziri.

• Nkwakọ ngwaahịa adịgboroja dị dabere na ọnụọgụ na atụmatụ achọrọ.

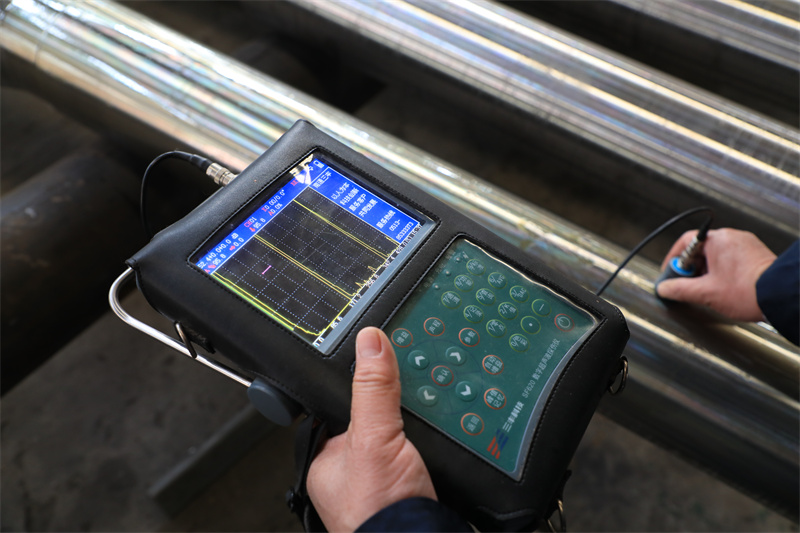

• A na-enyocha igwe igwe igwe ihe kwa biennium ma kwado ya n'aka ụlọ ọrụ anyị WELONG.

• Onye ọ bụla stabilizer nwere ule nodestructive ugboro ise (NDE).

Isi ihe

• AISI 4145H MOD, 4330, 4130, 4340, 4140, 8620 na wdg.

Usoro

• Ịmepụta + igwe siri ike + ọgwụgwọ ọkụ + Nnwale onwe onye + Nnwale nke ndị ọzọ + Nrụpụta Machining + Nleba ikpeazụ + Mbukota.

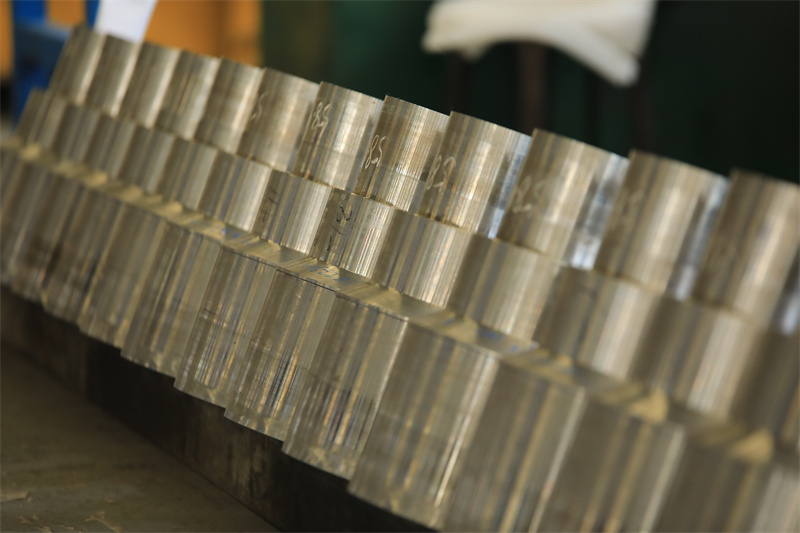

Ngwa

• moto stabilizer forging, stabilizer forgings, bit forgings, forging aro, forging mgbanaka na wdg.

Nhazi nha

• Ibu arọ nke ukwuu bụ ihe dịka 20T.Dayameta nke ịgha mkpụrụ bụ ihe dịka 1.5M.

Usoro ịhịa aka n'ahụ mepere emepe ahaziri iche

• kpo oku: The metal workpiece, a n'ụdị a mmanya ma ọ bụ billet, na-ekpo ọkụ na a kwesịrị ekwesị okpomọkụ na-eme ka ọ ọzọ malleable.Okpomọkụ a na-adịgasị iche dabere n'ụdị ọla a na-emepụta.

• Ịtụkwasị na Nhazi: A na-etinye workpiece na-ekpo ọkụ n'elu anvil ma ọ bụ elu dị larịị, na-eme ka nhazi nke ọma maka ịrụ ọrụ na-esote.

• Hammering: Onye na-eji ígwè arụ ọrụ na-eji ụdị hama dị iche iche, dị ka hama ike ma ọ bụ hama aka, na-akụ ma na-akpụzi ígwè ahụ.Hama na-afụ, jikọtara ya na iji nkà eme ihe, na-eme ka ihe arụ ọrụ ahụ ghọọ ọdịdị achọrọ.

• Reheating: Dabere na metal si Njirimara na mgbagwoju nke chọrọ udi, workpiece nwere ike mkpa ka reheated ọtụtụ ugboro n'oge forging usoro ịnọgide na-enwe malleability.

• Mmecha: Ozugbo emechara ụdị a chọrọ, enwere ike ịrụ ọrụ ndị ọzọ dị ka mbelata, ịkpụ, ma ọ bụ mmecha ndị ọzọ.